‘KALSI’ brand Three-Phase Electric Monoblock Centrifugal Pumpsets are ISI marked as per IS : 9079 having motor conforming to IS : 7538. These are single suction pumps designed and built on a complete unit on one shaft, thereby eliminating separate shaft and pump body making the unit more compact. Kalsi Centrifugal Monoblock Pumpsets are also manufactured of Super Power (high head & high speed) of 3000 RPM with insulation class ‘A’ and ‘B’.

Classifications

a. Kalsi Centrifugal Monoblock pumpsets of 1500 RPM, insulation class ‘A’

b. Kalsi High Head & High Speed Super Power Monoblock Pumpsets of 3000 RPM, insulation class ‘A’ c. Kalsi High Head & High Speed Centrifugal Monoblock Pumpsets of 3000 RPM, insulation class ‘B’

Application

- Agricultural farms

- Lawns & gardens

- Water supply

- Residential bungalows

- Sprinklers

- Industries

Salient Features

- Volute,motorbodyandend-coversaremadeofhightensilecastiron.

- Impeller having smooth interior surface finish for low friction losses.

- Motor windings are vacuum impregnated with synthetic varnish for better moisture resistance.

- Monoblocks designed to withstand voltage upto 320 volt.

- Better insulating materials used to withstand high temperature rise.

- Grease lubrication anti-friction ball bearings fitted to withstand radial and axial loads.

- Components machined to close tolerance on modern machines including CNC machines for reliable, consistent operations.

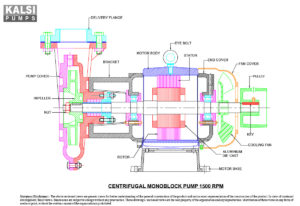

Constructional Details

- Motor frame : Frame is made of close grained graded cast iron and is totally enclosed fan cooled type. Adequate cooling ribs are also provided to facilitate heat dissipation of motor.

- Stator : It is built of hydraulically compressed high quality insulated lamination rigidly cleated, wound with super enamelled copper wire, impregnated with best quality stoving varnish and provided with high class insulating materials.

- Rotor : Rotor is squirrel cage type, die cast and dynamically balanced for vibration and noise free running.

- Casing : It is made of close grained cast iron of high tensile strength to withstand both working pressure as well as sudden impact. Its volute is well designed for high efficiency.

- Impeller : It is of single suction, enclosed type and dynamically balanced. Its interior passages are smoothly finished for high efficiency.

- Shaft : It is of high quality alloy steel, accurately machined and ground finished to close tolerances to ensure long life of bearings and gland packing. It is provided with a stainless steel sleeve which extends through the stuffing box.

- Stuffing box : Deep stuffing box accommodates sufficient graphite packing and thereby suction lift. It is water lubricated and sufficient space is provided for convenient repacking.

- Bearings : Heavy duty grease lubricated ball bearings with ample safety factor provided.

‘KALSI’ brand Three-Phase Electric Monoblock Centrifugal Pumpsets are ISI marked as per IS : 9079 having motor conforming to IS : 7538. These are single suction pumps designed and built on a complete unit on one shaft, thereby eliminating separate shaft and pump body making the unit more compact. Kalsi Centrifugal Monoblock Pumpsets are also manufactured of Super Power (high head & high speed) of 3000 RPM with insulation class ‘A’ and ‘B’.

Classifications

a. Kalsi Centrifugal Monoblock pumpsets of 1500 RPM, insulation class ‘A’

b. Kalsi High Head & High Speed Super Power Monoblock Pumpsets of 3000 RPM, insulation class ‘A’ c. Kalsi High Head & High Speed Centrifugal Monoblock Pumpsets of 3000 RPM, insulation class ‘B’

Application

- Agricultural farms

- Lawns & gardens

- Water supply

- Residential bungalows

- Sprinklers

- Industries

Salient Features

- Volute,motorbodyandend-coversaremadeofhightensilecastiron.

- Impeller having smooth interior surface finish for low friction losses.

- Motor windings are vacuum impregnated with synthetic varnish for better moisture resistance.

- Monoblocks designed to withstand voltage upto 320 volt.

- Better insulating materials used to withstand high temperature rise.

- Grease lubrication anti-friction ball bearings fitted to withstand radial and axial loads.

- Components machined to close tolerance on modern machines including CNC machines for reliable, consistent operations.

Constructional Details

- Motor frame : Frame is made of close grained graded cast iron and is totally enclosed fan cooled type. Adequate cooling ribs are also provided to facilitate heat dissipation of motor.

- Stator : It is built of hydraulically compressed high quality insulated lamination rigidly cleated, wound with super enamelled copper wire, impregnated with best quality stoving varnish and provided with high class insulating materials.

- Rotor : Rotor is squirrel cage type, die cast and dynamically balanced for vibration and noise free running.

- Casing : It is made of close grained cast iron of high tensile strength to withstand both working pressure as well as sudden impact. Its volute is well designed for high efficiency.

- Impeller : It is of single suction, enclosed type and dynamically balanced. Its interior passages are smoothly finished for high efficiency.

- Shaft : It is of high quality alloy steel, accurately machined and ground finished to close tolerances to ensure long life of bearings and gland packing. It is provided with a stainless steel sleeve which extends through the stuffing box.

- Stuffing box : Deep stuffing box accommodates sufficient graphite packing and thereby suction lift. It is water lubricated and sufficient space is provided for convenient repacking.

- Bearings : Heavy duty grease lubricated ball bearings with ample safety factor provided.

PDF Download(s)