Infrastructure

We as a group of companies shall strive to achieve leadership in design, development and distribution of various water pumping equipment, through continual improvement towards excellence and customer satisfaction.

Progressing towards stated objectives we strive to use our Quality Management System for :

- Manufacturing and timely delivery of consistent quality products and services as per customer requirements.

- Continual improvement in our products and processes.

- Training and involvement of our dedicated workforce.

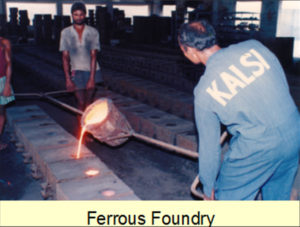

Foundry

Over the 57 years we have established cast iron metal knowledge to insure that all of our castings meet customer expectations. The castings are machined in-house CNC Machines. Foundry division is equipped with latest manufacturing processes & testing facilities. Our aim is to supply conformed products to our customers on time.

Product Capability

We produce castings as per BIS Standards.

- Casting Range : Cast Iron as per IS:210 and Bronze Castings.

- Capacity : 250 metric tonnes per month.

Manufacturing Facilities

We use CAD / CAM for design of Castings , pattern making , machining etc.

Moulding facilities

- Pressure Moulding Machines.

- Hand Moulding for heavy castings in nobake and CO2 moulding.

- Intensive Sand Mullers.

Melting Facilities

- Divided Blast Cupolas 2.5 – 3.0 Tons / hr. with Pollution Control Devices.

- Divided Blast Cupolas 2.8 – 3.2 Tons / hr. with Pollution Control Devices.

- Conventional Cupolas 2.2 – 2.5 Tons / hr. with Pollution Control Devices.

Core Shop Facility

- Core Shooter Machines.

- Air set Core.

- Cold Box Cores.

- Sodium Silicate Process.

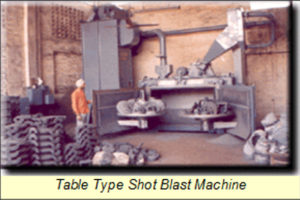

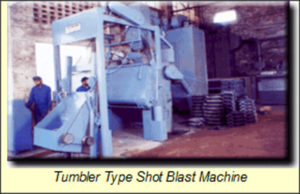

Fettling Facilities

- Tumbling type shot blasting machines.

- Rotary type shot blasting machines.

- Heavy duty frame type grinders.

- Pedestal Grinders

- Swing grinders.

- Portable Pneumatic grinders.

Pattern Shop Facility

We have in house pattern making facility. The pattern shop is equipped with following machines :

- Imported milling machine.

- Lathe Machines.

- Drill Machines.

- In house casting facility material used in pattern making.

Quality Control

A system has been applied in Foundry Section as per ISO 9001:2008. This system is for Continuous improvement and Foundry Section is on the improvement stream. All casted pieces are inspected before shot blasting and after shot blasting.

Metal Testing Facility

We have following metal testing facilities :

- On line temperature measuring meters.

- Hardness Tester.

- Chemical Analysis Laboratory.

- On line Carbon Silicon Analyzer.

Casting Classification

We are manufacturing a wide range of Castings in Cast Iron & Bronze.

Motor Part Casting

- For Submersible Pumpset : Upper Housing , Lower Housing , Connecting Piece , Rocker Plate, Motor Base.

- For Single Phase & Three Phase Monoblocks & Electric Motors : Motor Body , Pump Covers , Brackets, End Shields, Flanges , Motor Base

Pump Part Casting

- Impellers , Bowls , Discharge Outlet , Suction Case , Inlet.

Brass Casting

- LTB – 2 Casting

- LTB – 4 Casting

Quality Management

Our all sister concerns are ISO 9001:2008 companies which shows our commitment toward product quality and supply material to the customer on time and trouble free after sales service.

- All the process control instruments & equipments used in production / quality control is Calibrated at regular intervals to be sure that products are manufactured with consistent quality.

- We have strong Customer feedback system to take corrective & preventive action to see that our customers are totally satisfied.

- Through continual improvement towards excellence and customer satisfaction we train our dedicated work force.

- We are committed for continual improvement in our products & processes.

- We supply material on time for total customer satisfaction.

Following are some main Instruments / Tools / Equipments used in production

- Foundry : Carbon Silicon Analyzer , Green compression strength tester ,Green shear strength tester , Temperature measuring instruments , Core Hardness Tester , Boroscope , Mould Hardness Tester , Compatibility tester , AFS sieve Tester , Moisture Tester , Permeability Tester , Chemical Analysis Lab.

- Machine Shop : Slip Gauges , Outside Micrometers , Inside Micrometers , Height Gauges , Air Gauges , Depth Dial Gauges , Vernier Calipers , Dial Vernier Calipers , Dial Indicators , Pressure Gauges , Snap Gauges , Thread Plug gauges ,Thread Ring Gauges , Vacuum Gauges , Plug Gauges , Ring Gauges , Temperature Indicators , Bench Centers.

Performance Testing Facilities

- Digital Electromagnetic Flowmeters

- Digital Pressure Transmitters.

- Digital Tachometers

- Sound Testing Equipments

- Vibration Testing Equipments

- Digital Voltmeters

- Digital Ampere meters

- Digital Watt meters

Our products are 100 % tested.

Quality assuring tools & techniques used in production

In manufacturing quality is continuously improving due to our Total Quality Management programme. All the products are very strictly scrutinized and then they are sent for assembly. All final products are 100 % Hydraulic tested to ensure good quality of the products.